In PROTEUS PCB Layout Design ,many of PCB Shops do not know how to edit the CNC drill code??

It is true,that is why they refuse to accept PCB jobs edit from PROTEUS.

This workshop will show procedure how to generate Gcode for Mach3 CNC Machine Control.

สร้างไฟล์เจาะรู จาก PROTEUS ยังไง?ร้านทำ Print บางทีอาจยังไม่ทราบและต้องการรู้วิธีการ

รู้แล้วมีประโยชน์แน่นอน เพราะรู้แล้วรับงานจาก file ที่ออกแบบจาก PROTEUS ได้เลย.

Workshop :CNC Drill Gcode from PROTEUS.

What you can do when finish the work shop?

Know how to generate Gcode CNC PCB drill File from Proteus for Mach3 Operation.

Hardware Tools: CNC Driller/Milling Machine.

Softwere Tools: Proteus, Camtastic, Kcam4, Mach3

Procedure in brief.

- From PROTEUS: Edit Target File,Export Gerber and Exellon Drill files.

- From Camtastic:Import the files from PROTEUS,Edit and Generates modified Drill Files(Exellon).

- From Kcam:Import Exellon file from the above task,edit and save drill file in Gcode format.

- Edit the above Gcode to match Gcode used by Mach3 CNC .

- Mach3 mill:Open the work file from above task within Mach3 , run the Job and enjoy.

On Top Menu Output tab :export Gerber and Exellon for CADCAM Output layers as shown.

From Camtastic

Now, Panelize the PCB object from 1 to 6 panels.To do this.

On Top Menu bar Click ToolsàPanelize PCB : we will create 2x3 Panels PCB for our job for A4 layout work Area.This will match our CNC table top for A4 table size.If we have larger table size we may choose the appropriate layout size.

On Main Control menu Tab : click ReportsàDrill to see new Drill Report again.

On Top Menu bar ClickàEditàMove: to move the work objects to desire work area for our CNC table.Results as shown .

Note that: the objects of the work area are depend on particular table layout and set up for each machine.This set up is only for example.

Open to see the above drill file with Notepad.This exellon format drill file will be used by Kcam CNC Control Software.

Note:This format is 2:3 ,none leadind and trailing zero.

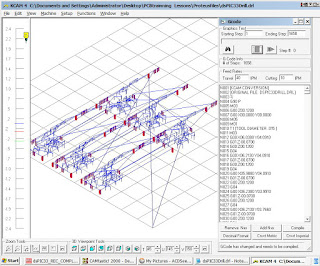

From Kcam

The result import work file can be edit and simulated in Kcam.On the right hand side of the figure show the Gcode file listing automatic generate by Kcam.

The result import work file can be edit and simulated in Kcam.On the right hand side of the figure show the Gcode file listing automatic generate by Kcam.Test Run for The simulation in Kcam.

This file will be edited and used by Mach3 CNC Control software in final work.

From Mach3 CNC Controller

So happy it works good.

PROTEUS PCB CNC Route--Gcode Generating for Mach3

to be continue ASAP.

ไม่มีความคิดเห็น:

แสดงความคิดเห็น